ZZ Group company has diversified production and supply capabilities. We can meet the needs of different customers, follwing the market changes, ZZ Group company keeps updating its own products to ensure that we can provide products and services of high quality and efficiency consistent with the markt demand.

With the development of the market and the renewal of products, ZZ Group company has also made corresponding adjustments to its own technology theory and existing technology to meet the needs of the market .

ZZ Group cooperate with the spirit of partnership in mind while working closely with our customers and industry professionals to develop custom products. Our success is proven by repeat customers who continually employ ZZ Group to develop products that meet or exceed expectations.

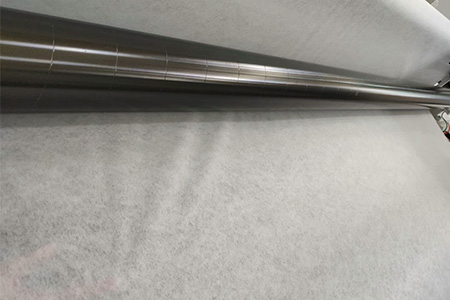

PE film +SMS

PE partial composite non woven fabric

PE film+untrosonic fabric

PE film+super Hydrophilic fabric

PE melt glue composite

maximum width: 94.5"(2.4m)

weight: 30g/sm-200g/sm

Slitting/Rewinding (maximum width: 126" and minimum width: 0.79" with tolerances±0.12")

Paper core: 3"Diameter ,thickness: 0.24"

PE shrinkable film packing: tight, smooth, clan, neat